Entropea Labs provides standard compact heat engine power units in the small and medium power range. Entropea’s standard units can be customized to provide turnkey solutions that meet the reliability requirements of our customers at low cost.

Entropea Labs uses state-of-the-art tools and collaborates with leading academic institutions, research centres and industrial partners to develop, assemble and test the compact heat engine power units. Our team develops the Organic Rankine Cycle the Control System and the Heat exchangers and Turbo-expander, if required. The rest of the components of Entropea’s power systems are all industry standard components. Entropea’s approach significantly reduces costs & lead times for bringing a system from concept to design and manufactured product.

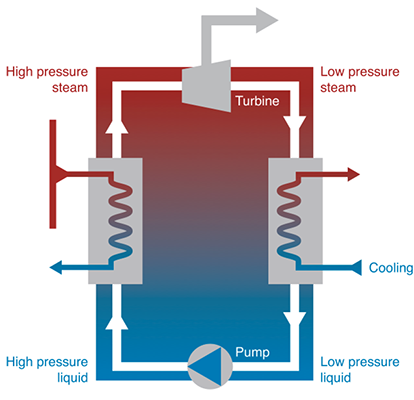

What is an ORC?

Rankine cycles have been used throughout the industrial history to convert thermal energy into kinetic energy and/or electricity. Rankine cycles work by evaporating a working fluid at a high pressure (cycle top pressure), energy is subsequently extracted from the working fluid by means of an expansion process (pressure reduction to bottom pressure), and finally the working fluid is condensed and re-pressurised thus resetting the thermodynamic cycle.

ORCs employ an Organic Fluid undergoing the same thermal processes as the standard Rankine cycle, where water is used as the working fluid. Different organic fluids have different state and phase-change properties. For example, organic fluids may be used as refrigerants if they evaporate at very low temperatures; or they can be used in the context of Concentrated Solar Power (CSP) and or Waste Heat Recovery (WHR) from low-grade energy sources, such as geothermal applications. Organic fluids can therefore be chosen depending on the type of heat source and its duty cycle.

Entropea Labs has created models, which can optimise thermodynamic cycles performance based on power output and components costs. This includes optimization of a thermal cycle, fluid selection, component selection/sizing/rating, transient cycle analysis and optimization.

Turboexpanders

Preliminary 2-D design, CFD design, CAD/CAM design, manufacturing and testing of turbines driven by steam or organic fluids is achieved with our state of the art computer codes developed by our team and research partners.

The turboexpander and generator are directly coupled and rotate at very high speeds. The high speeds enable compactness, whilst retaining very high efficiencies for the turboexpander.

Heat Exchangers

Entropea specialises in the development of high-pressure high temperature heat exchangers. Entropea’s heat exchangers have been exposed to extreme conditions (e.g. high temperature exhaust gases), retaining their effectiveness.

Entropea’s heat exchangers have been designed and tested to have zero invasiveness and provide minimal backpressure to the genset engine exhaust gases.

Preliminary concept design, CFD design, CAD/CAM design, manufacturing and testing of unconventional heat exchangers are achieved using state of the art computer codes developed by our team and research partners.

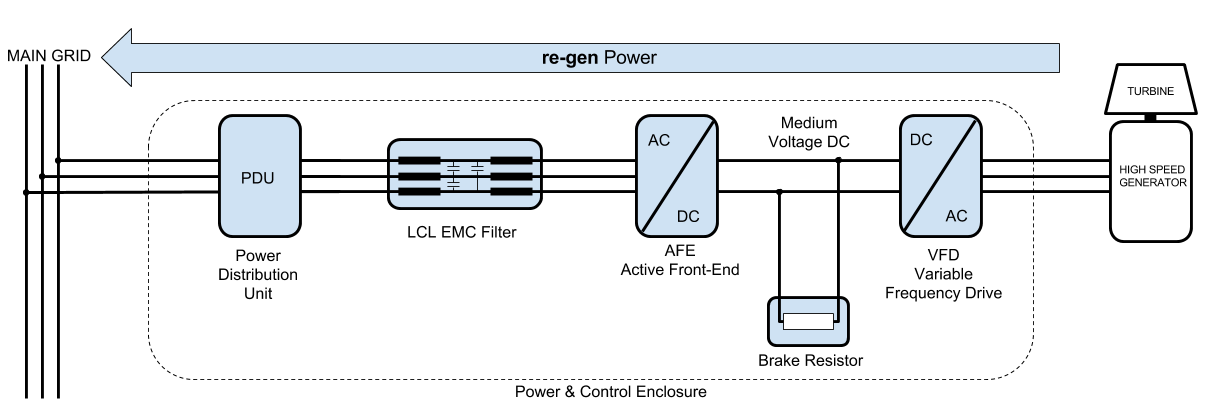

Power & Control Systems

Entropea’s engineering team develops the architecture of the power systems to condition the electrical power output to match final utilization.

A close collaboration between the departments results in optimum dedicated embedded control systems for the thermodynamic Rankine cycle.

High frequency inverters are used for high efficiency energy conversion and industry standard PLCs offer high reliability of the ORC controller. Entropea’s re-gen system is very easily interfaceable with our customer’s PLC via industry standard communication protocols.

Entropea’s compact heat engine power unit‘s electrical conversion system is based on two back-to-back static power converters. The AFE (Active Front-End) is a power converter that provides bidirectional power flow between the grid and a DC link. With the addition of the LCL EMC filter, the system provides perfectly sinusoidal currents that automatticaly syncronise with the grid. Protectve disconnecting devices are added as part of the PDU (Power Distribution Unit).

The ORC based heat engine system provides power to the turbine wich connected to the generator feeds the DC link through the generator’s VFD (Variable Frequency Drive). In case of grid loss, the PDU automatically disconnects the heat engine power system and the turbine is brought to a controlled stop during which the power is disippated on a braking resistor.

Entropea offers complete solutions for interfacing and transferring power generated by the ORC that suit client’s requirements. Connections to grid or microgrid are possible through dedicated active front ends. Connections through DC bus are also possible. All equipment selected by Entropea will meet relevant standards and regulations.

Typical simplified grid connection of Entropea’s heat engine power units.